Forging Excellence in Welding and Engineering Services

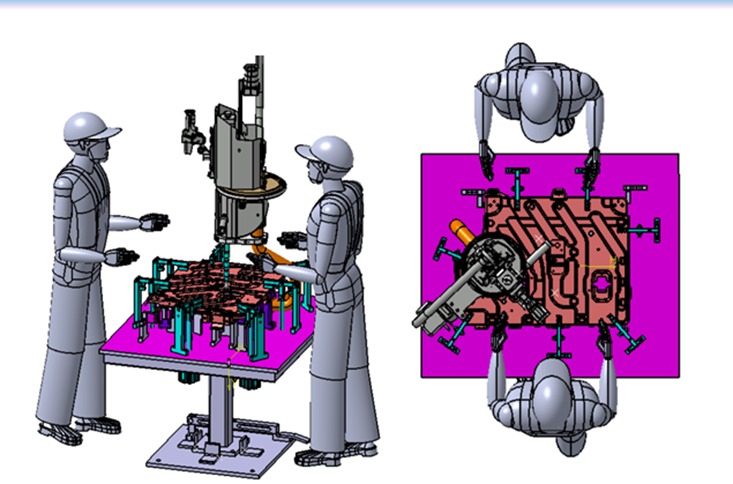

Involves complete body shop planning with the layout, logistics, panel build/flow chart, weld spot selection / distribution, clamping plan / location plan, cycle time study & operator ergonomics study.

Involves complete body shop planning with the layout, logistics, panel build/flow chart, weld spot selection / distribution, clamping plan / location plan, cycle time study & operator ergonomics study.

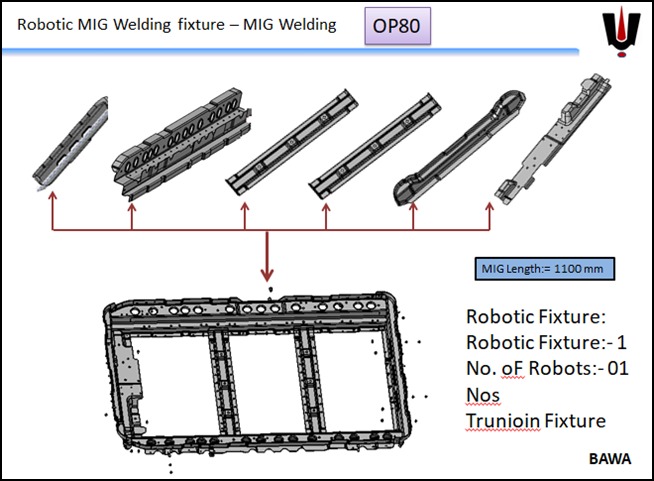

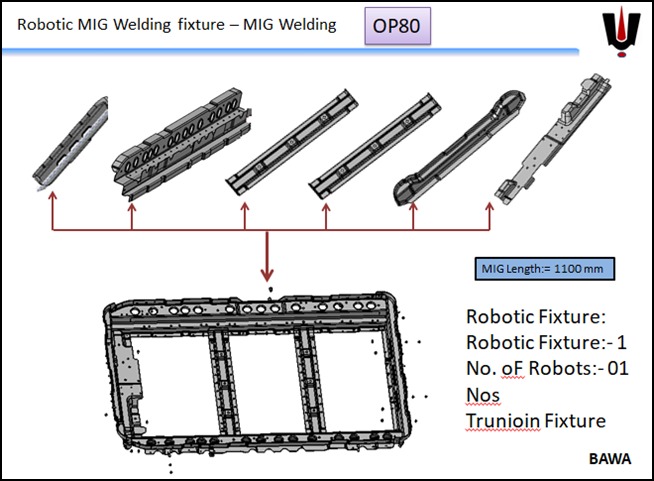

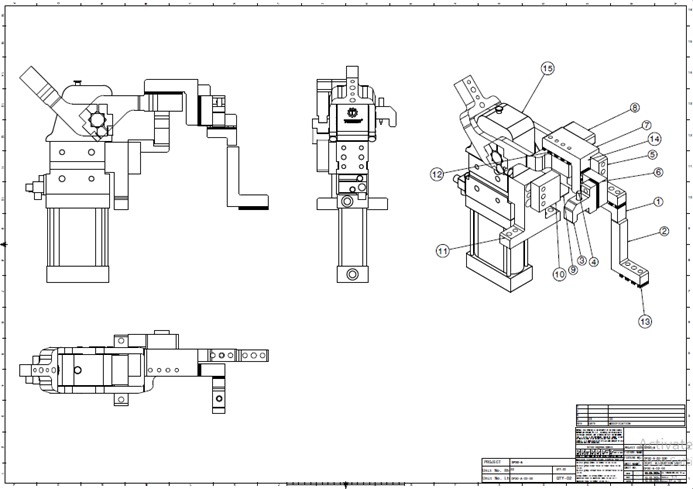

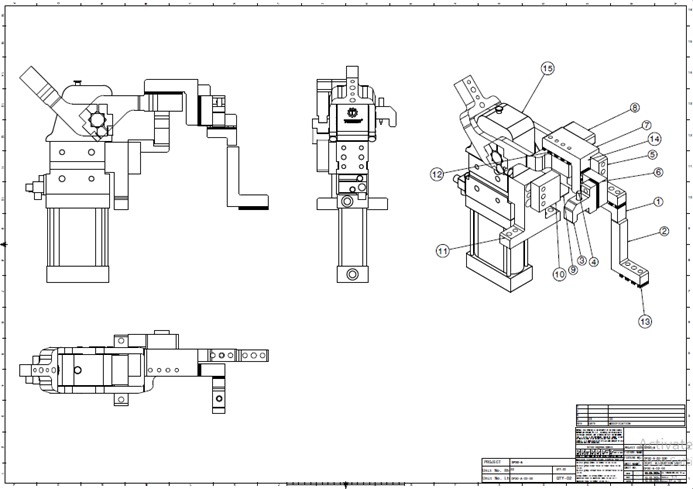

Involves designing jigs/fixtures, robot grippers and other equipments as per the plan, required in the BIW welding line. It also includes conducting internal design reviews to optimize the design in terms of its weld accessibility, operator ergonomics and quality. It involves interacting with the Robot Simulation Engineers for Robot reachability with minimum repositions. Finally, its role is in conducting DAP with customer for getting approvals to go ahead for manufacturing.

3D Design

Involves designing jigs/fixtures, robot grippers and other equipments as per the plan, required in the BIW welding line. It also includes conducting internal design reviews to optimize the design in terms of its weld accessibility, operator ergonomics and quality. It involves interacting with the Robot Simulation Engineers for Robot reachability with minimum repositions. Finally, its role is in conducting DAP with customer for getting approvals to go ahead for manufacturing.

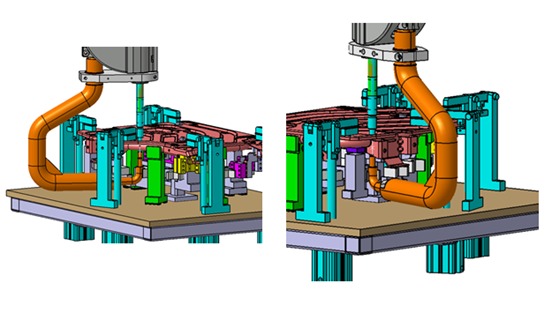

The team creates optimized robot cell in terms of the layout space, payload and reachability. This step supports customers in the selection of robots based on the payload and reachability. It creates a robot path, interacts with the design team for any modifications and after finalization, creates OLP (Offline Robot Program) for quick installation of line.

The team creates optimized robot cell in terms of the layout space, payload and reachability. This step supports customers in the selection of robots based on the payload and reachability. It creates a robot path, interacts with the design team for any modifications and after finalization, creates OLP (Offline Robot Program) for quick installation of line.

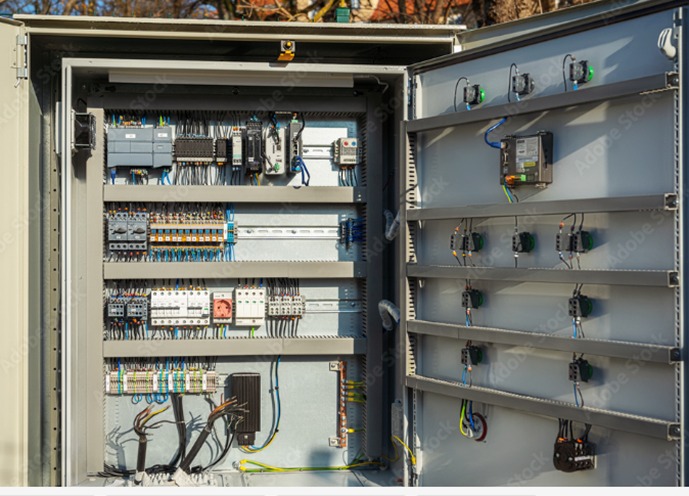

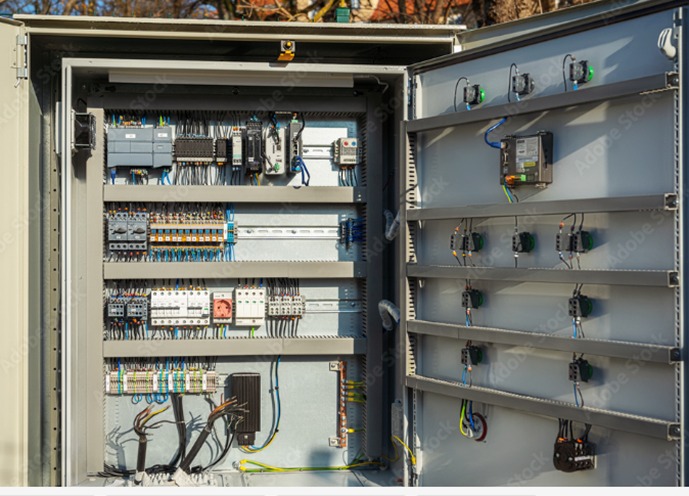

The automation team starts their work on any project from the Controls Design, as per the standards and requirements of the customers. They also create pneumatic circuits for Jigs/Fixtures and get it approved by the customer in DAP.

Controls Design

The automation team starts their work on any project from the Controls Design, as per the standards and requirements of the customers. They also create pneumatic circuits for Jigs/Fixtures and get it approved by the customer in DAP.

After getting customer approvals on the 3D Designs, we create manufacturing drawings with the BOM (Bill of Material). Also, we support customers with NC Patch Data / IGES models of NC Blocks preparation for manufacturing, inspection data & inspection sheet preparation and preparation of cylinder and sensor sheet (Pneumatic Circuit diagram & Sensor Logic Matrix).

After getting customer approvals on the 3D Designs, we create manufacturing drawings with the BOM (Bill of Material). Also, we support customers with NC Patch Data / IGES models of NC Blocks preparation for manufacturing, inspection data & inspection sheet preparation and preparation of cylinder and sensor sheet (Pneumatic Circuit diagram & Sensor Logic Matrix).

Balaji Automotive Welding and Assemblies(BAWA)

Ground Floor Gat no: 454 Shade no-8 Raje Shiv Chhatrapati Vidhyalay Road, Tukaram Nagar , Talawade, Pimpri Chinchwad Pune Maharashtra, India 411062

BAWA AUTOMATION Limited Company, LLC

1309 Coffeen Ave STE 14032, Sheridan, WY, 82801, USA

Incase of any questions related to our offerings you could mail us.

sales@bawaautomation.com balajiautomotivewelding@gmail.com

For further queries you could connect with us by call us on +917507897711.

we are available on Monday to Sunday ( 8.30 am to 7 pm)