Your Trusted Partner in Welding Manufacturing Excellence.

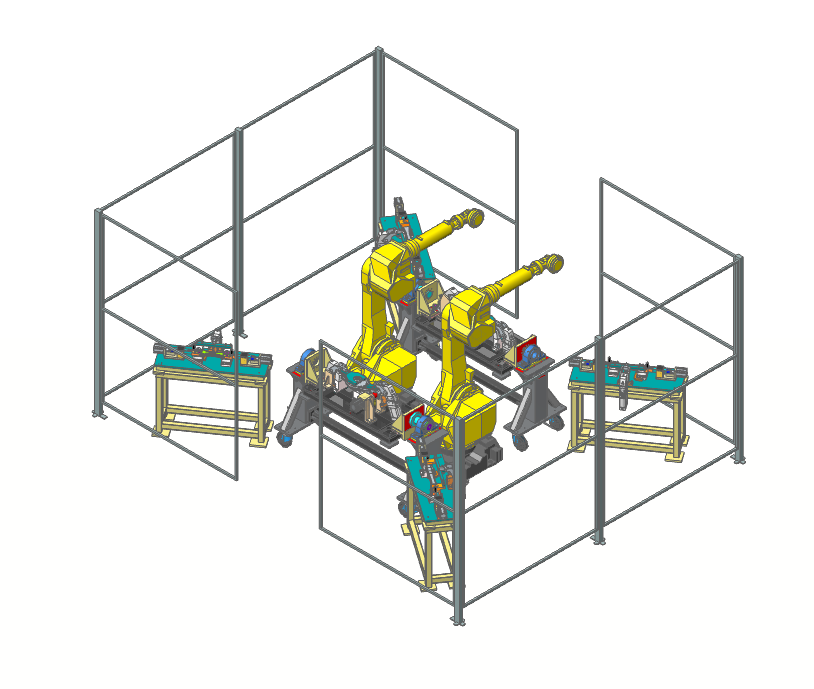

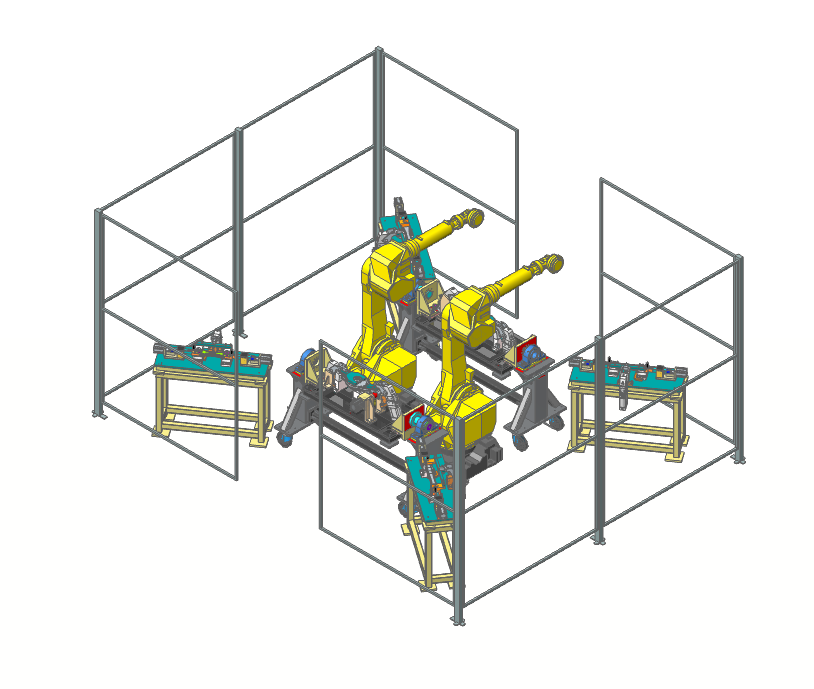

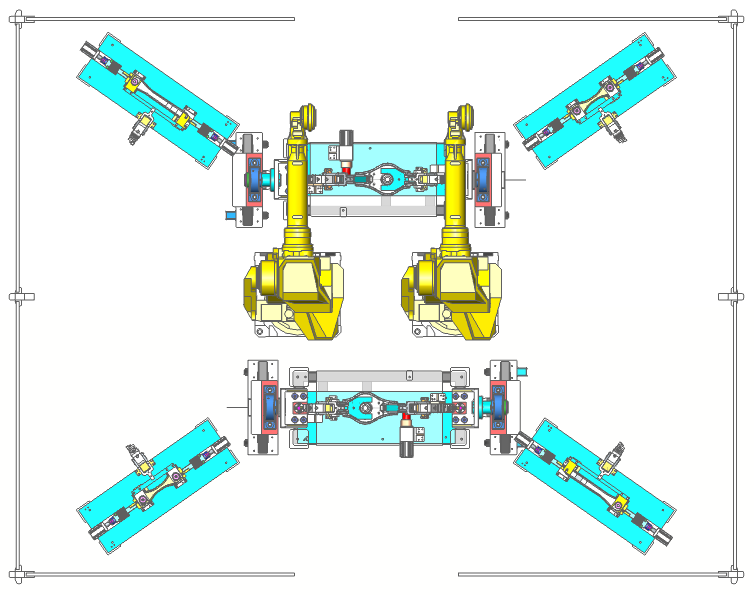

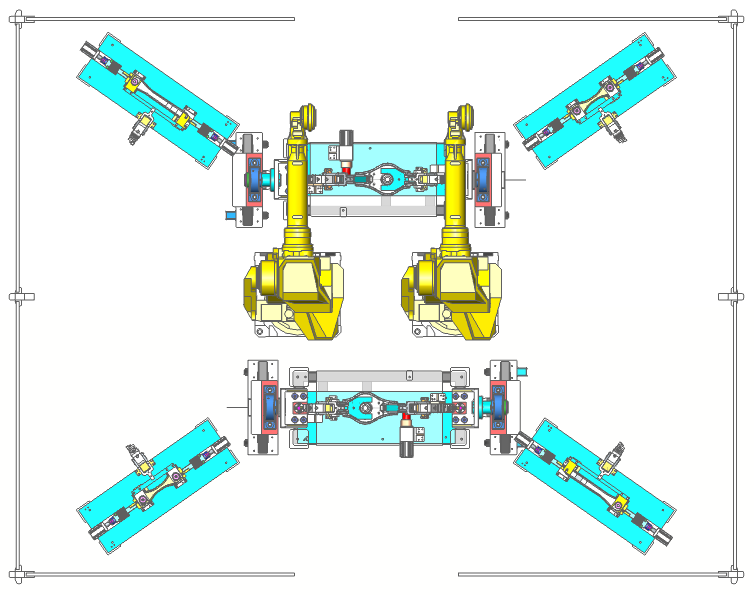

Robotic MIG welding solutions are offered, mainly for Chassis & Underbody safety assemblies like Chassis, Rear Axle - RTB, Sub Frames - FCM and Lower Cross Arm - LCA. The team of experts at Bawa possess advanced skills in the robotic MIG welding lines. The team has many years of experience in executing MIG Welding Projects. As a result of this, the team can achieve best results with good penetration & minimum distortion. The robotics team at Bawa have the experience of working with different combinations of robots and welding sources like Fanuc+ Lincoln, KUKA + Fronius, Panasonic etc.

Robotic MIG welding solutions are offered, mainly for Chassis & Underbody safety assemblies like Chassis, Rear Axle - RTB, Sub Frames - FCM and Lower Cross Arm - LCA. The team of experts at Bawa possess advanced skills in the robotic MIG welding lines. The team has many years of experience in executing MIG Welding Projects. As a result of this, the team can achieve best results with good penetration & minimum distortion. The robotics team at Bawa have the experience of working with different combinations of robots and welding sources like Fanuc+ Lincoln, KUKA + Fronius, Panasonic etc.

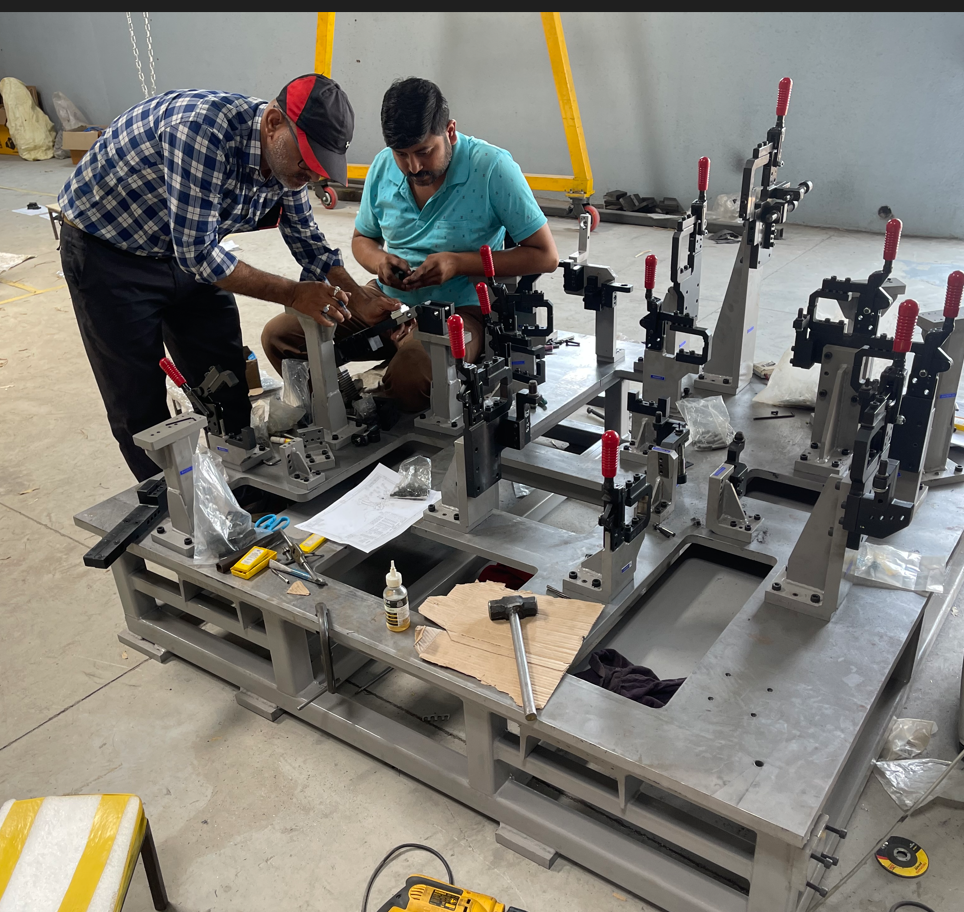

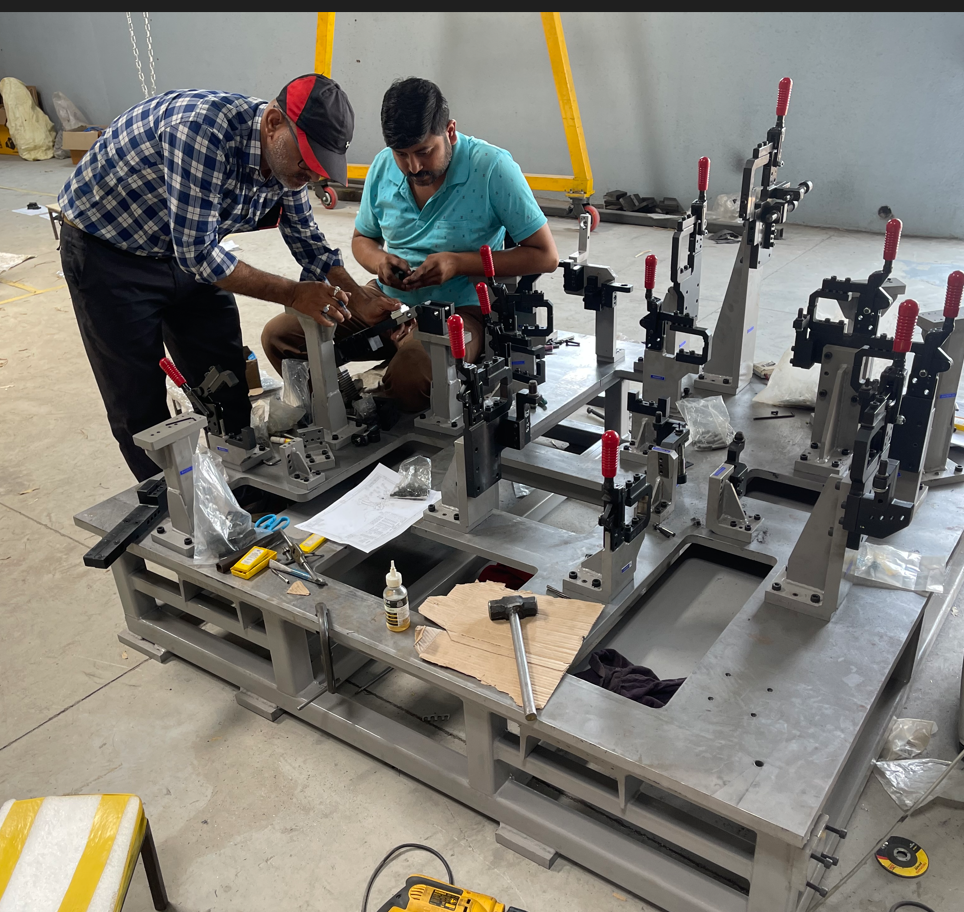

For low volume/low JPH (jobs-per-hour-rate) lines, We offer Manual Spot Welding Lines/Fixtures/Jigs. The design team takes utmost care of operator ergonomics (like loading height, reach, gun orientation and handling) as well as fatigue, while designing these manual welding fixtures/jigs. Manual Spot Welding Lines is for low volumes and the complete Bodyshop Solutions is provided.

Manual Spot Welding Lines - BIW

For low volume/low JPH (jobs-per-hour-rate) lines, We offer Manual Spot Welding Lines/Fixtures/Jigs. The design team takes utmost care of operator ergonomics (like loading height, reach, gun orientation and handling) as well as fatigue, while designing these manual welding fixtures/jigs. Manual Spot Welding Lines is for low volumes and the complete Bodyshop Solutions is provided.

MIG welding is one of Bawa's strong competencies, where robotic MIG welding solutions are offered, mainly for Chassis & Underbody safety assemblies like Chassis, Rear Axle - RTB, Sub Frames - FCM and Lower Cross Arm - LCA. The team of experts at Bawa possess advanced skills in the robotic MIG welding lines. The team has many years of experience in executing MIG Welding Projects. As a result of this, the team can achieve best results with good penetration & minimum distortion. The robotics team at Bawa have the experience of working with different combinations of robots and welding sources like Fanuc+ Lincoln, KUKA + Fronius, Panasonic etc.

MIG welding is one of Bawa's strong competencies, where robotic MIG welding solutions are offered, mainly for Chassis & Underbody safety assemblies like Chassis, Rear Axle - RTB, Sub Frames - FCM and Lower Cross Arm - LCA. The team of experts at Bawa possess advanced skills in the robotic MIG welding lines. The team has many years of experience in executing MIG Welding Projects. As a result of this, the team can achieve best results with good penetration & minimum distortion. The robotics team at Bawa have the experience of working with different combinations of robots and welding sources like Fanuc+ Lincoln, KUKA + Fronius, Panasonic etc.

Balaji Automotive Welding and Assemblies(BAWA)

Ground Floor Gat no: 454 Shade no-8 Raje Shiv Chhatrapati Vidhyalay Road, Tukaram Nagar , Talawade, Pimpri Chinchwad Pune Maharashtra, India 411062

BAWA AUTOMATION Limited Company, LLC

1309 Coffeen Ave STE 14032, Sheridan, WY, 82801, USA

Incase of any questions related to our offerings you could mail us.

sales@bawaautomation.com balajiautomotivewelding@gmail.com

For further queries you could connect with us by call us on +917507897711.

we are available on Monday to Sunday ( 8.30 am to 7 pm)